Forecast performance in the future to enhance decision-making in the present.

Embrace predictive methods to enable proactive decision-making for your chemical plant.

Due to shifts in market demand, pricing fluctuations, and growing emphasis on decarbonization and adopting circular economy practices, chemicals companies are reevaluating their operations. In this evolving landscape, they are tasked with finding innovative approaches to reduce waste, emissions, minimize downtime, and enhance profit margins, ultimately gaining a competitive edge while lessening their environmental footprint. To achieve this, it’s essential that every aspect of their operation, from the factory floor to the enterprise level and across processes and personnel, gains access to the right tools and insights to become more adaptable than ever.

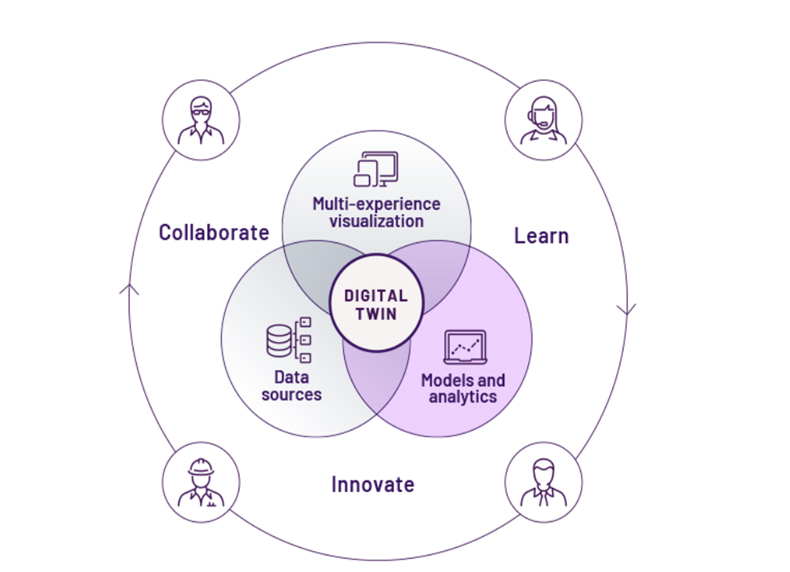

So, how can chemicals companies, especially those with well-established optimized processes, discover fresh ways to confront the current challenges? The key is innovation. By harnessing the right data, visualization techniques, and employing models and analytics strategies, chemical operators can foresee future performance, leading to more informed decisions in the present.

Innovation isn’t solely a strategy for the distant future.

Innovation is not limited to long-term strategies alone. Companies must also embrace a short-term perspective, and the most effective approach is to leverage digital technology to offer every stakeholder a clear understanding of their existing data, assets, and processes. This empowers them to drive continuous improvements throughout each moment of every day.

Chemical companies with a robust data infrastructure that provides contextualized data access have a competitive advantage. With insights into both historical and real-time operations, users can model and anticipate future performance and take proactive steps towards achieving profitability and sustainability goals. When chemical operations harness the right data for generating insights, organizations can prioritize digital initiatives, and users can make informed decisions, ultimately fostering greater adaptability within their facilities.

To predict future plant performance and achieve today’s objectives, a three-step approach to digital initiatives is necessary:

Data: The initial step involves aggregating operational data from various sources and formulating a digital strategy for continuous improvement. Many TROT INDIA clients employ the TROT INDIA PI System, which serves as a unified source of truth for all operational data, granting users access to a contextualized environment housing all relevant data.

Visualization: Once data is centralized within a comprehensive data management framework, users require the appropriate tools to visualize data and key performance indicators (KPIs). Today, users throughout the organization can access and visualize data and KPIs, whether through full-screen displays or handheld tablets.

Models and Analytics: By employing models and analytics, users can utilize current and historical data to predict plant and asset behavior. With the assistance of TROT INDIA Predictive Analytics, chemical operations can acquire valuable insights and guidance regarding the necessary actions to maintain stable, profitable, and sustainable operations, aligned with overarching business strategies. Taking it a step further, the adoption of TROT INDIA Process Simulation provides decision-makers with insights into process variables that cannot be directly measured, enabling proactive prediction of reliability issues.

Chemical companies have a range of digital resources at their disposal, offering diverse modeling methodologies that are both swift and straightforward to adopt. These tools encompass conventional thermodynamic equations as well as cutting-edge machine learning models. By equipping their teams with the most effective modeling and analytics tools, chemical companies can drive proactive decision-making, yield significant short-term advantages, and lay the foundation for a cohesive, profitable, and sustainable future.

Discover how the application of models and analytics can expand the utility of your data.

Speak With an Expert

Get in touch with a product specialist from TROT INDIA to gain deeper insights into our product offerings.