Predictive Analytics Pilot Phase

Advancing Beyond the Pilot Phase in Predictive Analytics

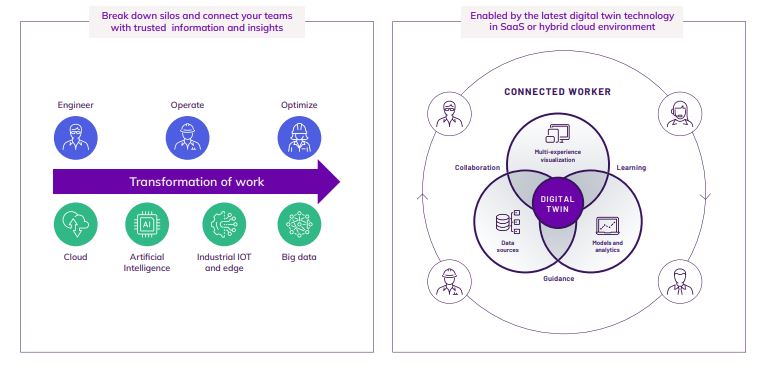

Regardless of an organization’s future goals, it is crucial to incorporate predictive and prescriptive maintenance strategies into its growth plans. Effective predictive maintenance strategies emphasize integrated solutions that break down industrial data silos, optimize workforce productivity, and facilitate ongoing operational enhancements. As workforces adapt and change, the decision-making systems employed by enterprises should integrate new technologies that make data more accessible to all, promoting improved collaboration and instilling confidence in faster, more precise decision-making.

Maximizing the potential of your data

Many organizations struggle with ineffective utilization of the wealth of data at their disposal. To address this challenge, enterprises should establish a unified information platform that seamlessly connects all available data sources, enabling them to extract maximum value from their information assets.

When companies have access to a centralized source of real-time data spanning their entire operation, it fosters connectivity among their workforce, facilitates the preservation of collective knowledge for ensuring operational reliability, and uncovers fresh insights for optimizing business functions. The unification of all data sources creates a digital thread that empowers engineering and operations teams to:

Gather, aggregate, and contextualize extensive volumes of data.

Break down the barriers between engineering and operations data, eliminating data silos.

Extract novel insights that encompass the complete asset life cycle, encompassing engineering, operations, maintenance, and decommissioning.

Enhance data with artificial intelligence (AI) and machine learning (ML) for predictive and prescriptive analytics.

Seamlessly visualize information throughout the organization within a unified interface.

By infusing this digital thread with predictive models, AI-powered analytics, and multi-experience visualization, a digital twin is created. A digital twin serves as a digital representation of real-world physical products, systems, or processes. It offers insights that span the entire life cycle of assets, from initial capital projects and engineering to ongoing operations and optimizing asset performance.

Leveraging a digital twin can significantly expedite an organization’s predictive analytics initiatives, as data, predictive models, analytics, and visualization are standardized and readily accessible for use.

TROT INDIA

Analytical software provides rapid outcomes.

Frequently constrained by limited resources, decision-makers seek to initiate projects that yield swift results and a favorable return on investment (ROI).

The adoption of AI and ML technologies has the potential to significantly reduce unplanned downtime, lower maintenance costs, enhance workforce safety, and promote sustainable operations. Enterprises leveraging these technologies often witness a reduction in operational expenditure (OpEx) by as much as 20%.

Many organizations embark on their predictive maintenance journey by starting with condition-based monitoring, which centers on real-time conditions and sensor measurements. In contrast, AI and ML prioritize the early identification of issues through the application of precise models grounded in historical data and current asset health information.

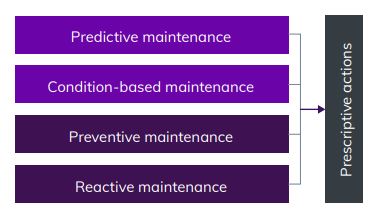

A sustainable maintenance strategy typically entails a combination of reactive, preventive, and predictive maintenance approaches, customized to the risk profile and criticality of a specific asset. Depending on the asset’s importance to the business, a run-to-failure approach may be suitable for certain assets, while others may necessitate more advanced maintenance, contingent on factors such as asset criticality and part availability.

- Scalability, User-Friendliness, and Sustainability: When the time arrives to expand the reach of analytics, teams may encounter challenges in managing the substantial data volumes, the ongoing maintenance demands, and the deployment of predictive models across their production lines. The user-friendliness, sustainability, and deployability of predictive analytics software play a pivotal role in sustaining and optimizing a viable analytics program.

Businesses need to evaluate how to effectively roll out different maintenance strategies on a larger scale. What is the most efficient manner for managing various strategies within the system? How will different stakeholders apply insights derived from diverse analytics? How straightforward is it for stakeholders to respond to predictive alerts? How does the system adapt to changes?

5. Scalability: Advancing beyond the pilot phase necessitates a scalable approach. When working at a larger scale, implementing predictive analytics integrated with the digital twin reduces the time required to realize value and encourages a systematic approach to the deployment, utilization, and maintenance of the program.”

Advancing Beyond the Pilot Phase in Predictive Analytics

Transitioning past the initial pilot phase

Numerous enterprises have initiated pilot projects as their initial steps in implementing predictive analytics technology. However, some of these companies encounter challenges in advancing beyond this pilot phase. On the contrary, early adopters of predictive analytics solutions have achieved remarkable results and have surpassed their competitors. They continue to reap the benefits of compounding insights.

The effectiveness of a predictive analytics program hinges on several critical factors. The program’s success relies on the deployability, usability, maintainability, and scalability of predictive analytics efforts. To seamlessly progress from the pilot phase to a profitable, organization-wide implementation, enterprises seek:

- Open, standards-based connectivity: A successful AI program necessitates a comprehensive approach to data and analytics integration. Mere adaptation of a set of point solutions with proprietary connectivity options falls short. An open, agnostic data infrastructure enables the connection of all data sources and their inclusion in analytics, ensuring a complete view without undermining prior technology investments.

- Data aggregation, contextualization, and visualization capabilities: Transforming large volumes of data into meaningful insights is pivotal. Employees must be able to comprehend the data they collect and its practical applications in enhancing operational reliability. A digital thread delivers role-specific contextualized information and furnishes complete visibility into real-time asset health, operations, and asset life cycles through a unified interface.

- A prioritized maintenance strategy: A comprehensive maintenance strategy should encompass a blend of reactive, preventive, condition-based, and AI and machine learning techniques that align with the risk profiles of assets. To pinpoint where predictive efforts should be invested, enterprises should gain insight into the assets’ criticality in terms of business success.

With an understanding of the criticality of their assets, businesses can discern how and where to deploy various building blocks in a predictive maintenance strategy that can yield the greatest impact.

Conclusion

When effectively implemented, predictive analytics solutions consistently yield a substantial return on investment. The question is no longer whether to initiate a predictive maintenance journey but rather how to do so. In today’s fast-evolving market landscape, organizations must cultivate adaptability and operational efficiency, and the challenge of unplanned downtime remains a substantial obstacle for operations and maintenance managers.

To fully capitalize on a predictive maintenance initiative, organizations should adopt a forward-thinking approach and prepare for the future in collaboration with a partner capable of guiding their predictive analytics program through the initial pilot phase and beyond.

Advancing Beyond the Pilot Phase in Predictive Analytics

End unplanned downtime: Best practices for asset failure mitigation

Use TI Predictive Analytics fault diagnostics to plan maintenance strategies